GWFS-V12

Friction shims

Application:

Friction joints,Shear joints applied in the base,Flange connections,Central bolt connections,Bolt connections,Fastener,systems,Various mating surfaces: metal, electronic coatings, and composite materials.

With the increasing demand for maximum power density, such as transmitting greater forces and torques in compact structures, engineers across various industries face significant challenges. JiaoKai provides solutions that increase friction to withstand higher shear forces at connection points or transmit greater torque at bolt connections. JiaoKai friction shims offer a simple and cost-effective method to increase the transmitted torque or force by 3 to 5 times compared to traditional systems, without the need to modify the joint design.

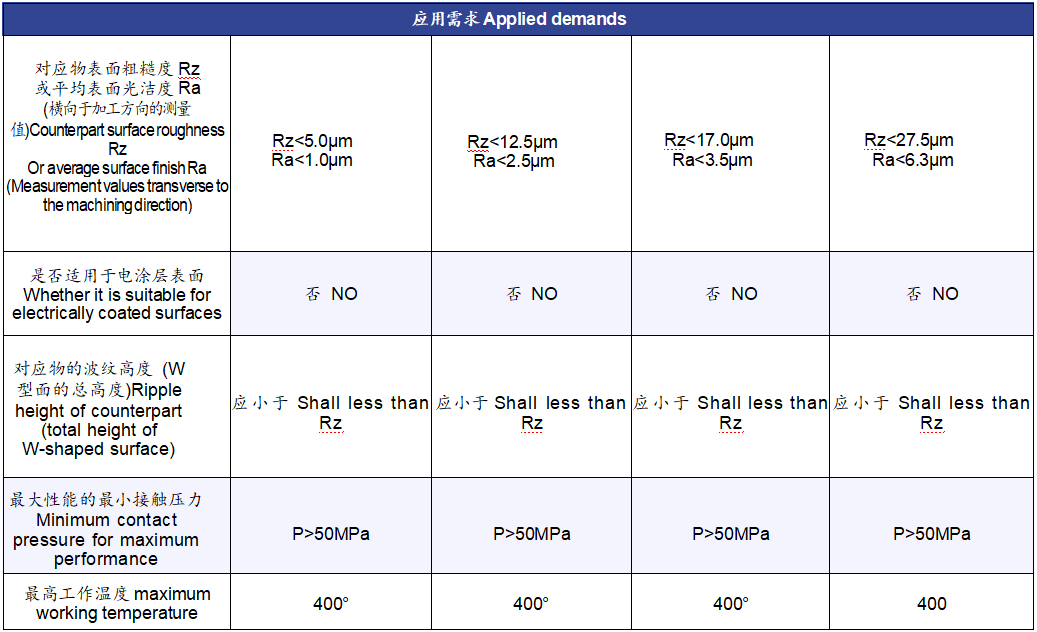

Jiao Kai friction shims are made from a nickel-coated steel base, partially embedded with diamonds, which create a micro interlock with the mating surface as they shrink. These shims are easy to assemble and can be reused after disassembly. They are sufficiently thin to achieve a perfect fit with tolerances. The lightweight, compact design increases the maximum load and peak torque of bolt connections.

Jiao Kai friction shims have proven to be reliable and effective across various industries, including automotive, general mechanical engineering, machine tools, marine engineering, wind and hydropower generation, and aerospace. Our technical experts possess years of application experience and internal testing methods.

Significantly improves the static friction coefficient.

Unaffected by oil film.

Easy to retrofit and upgrade.

Prevents micro-vibration wear.

Available in deep gray for a unique appearance.

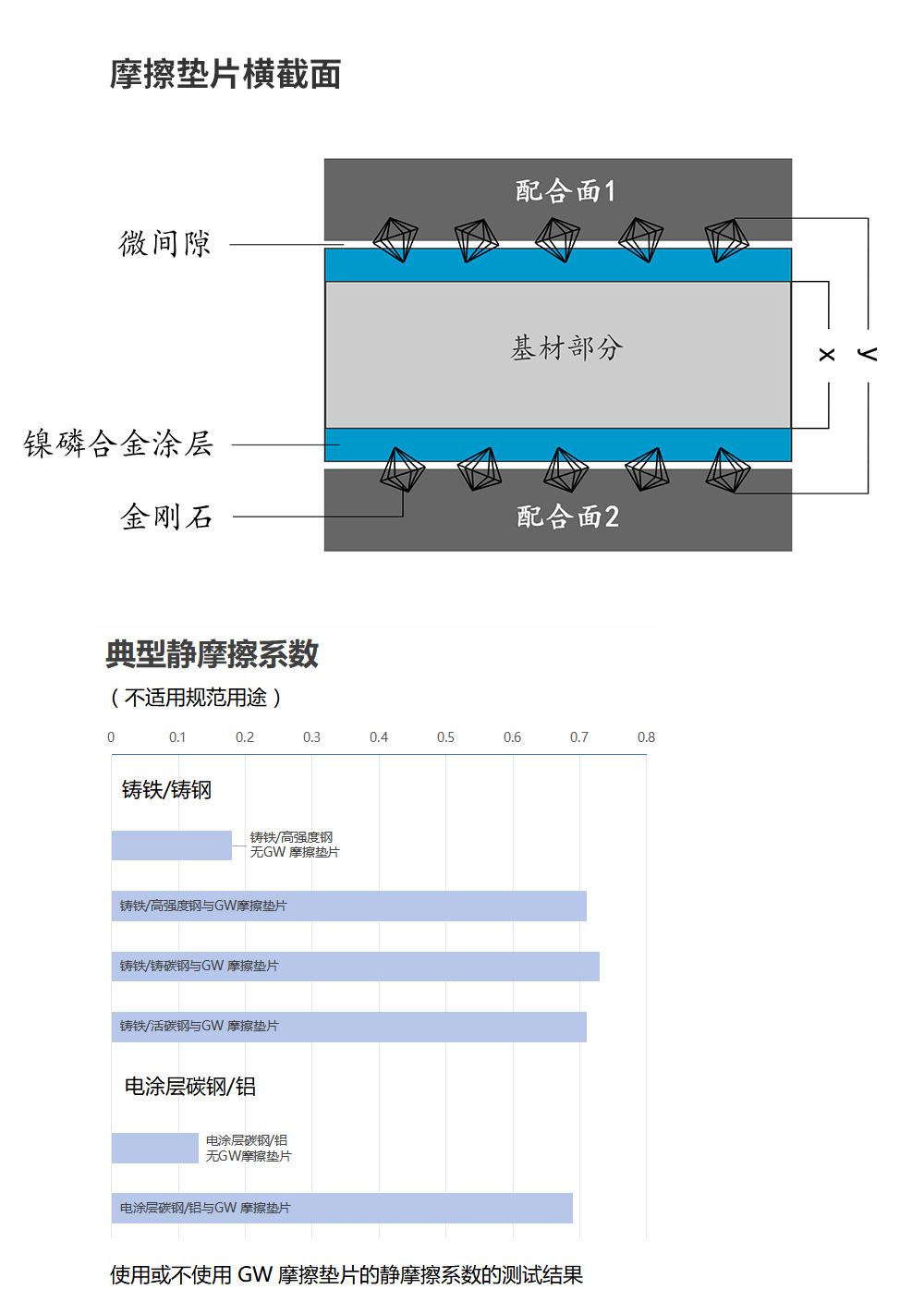

Friction gasket geometries can be customized according to customer requirements.

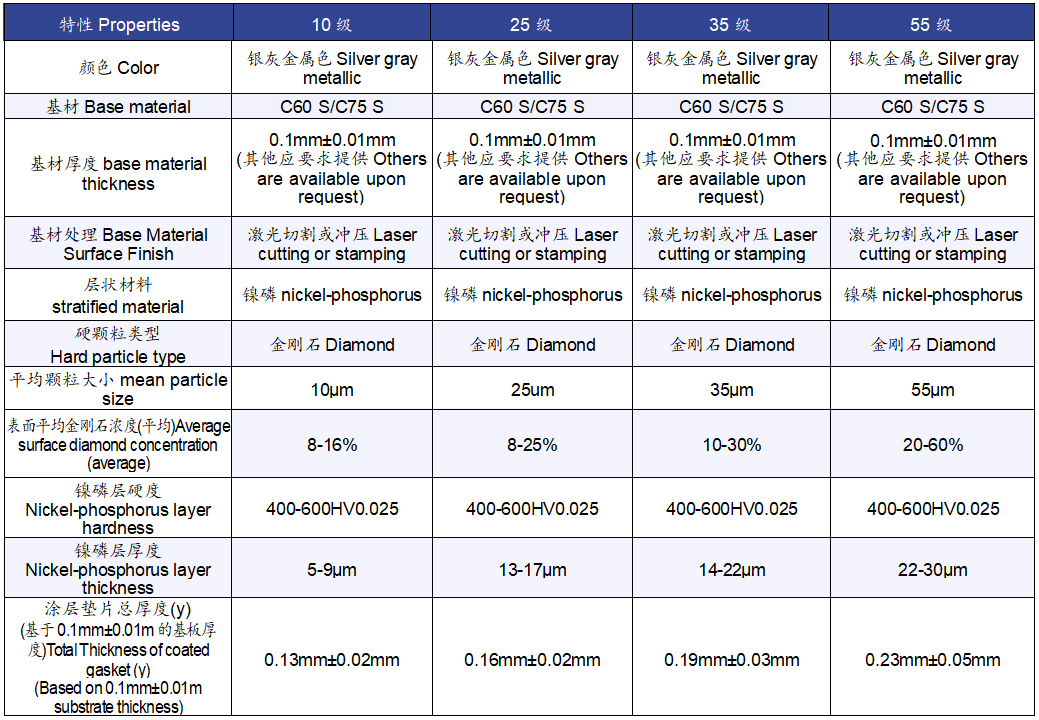

To achieve optimal performance, the mating surfaces must meet the roughness value \( R_z \) specified in the parameter table.

It is recommended that the contact pressure be at least 50 MPa to achieve the maximum static friction coefficient.

JiaoKai offers technical application support and can provide laboratory friction testing.

Scanning Electron Microscope (SEM) Images of Guwang Friction shims and Nickel-Diamond Coatings.

Store GW gaskets in their original packaging.

Do not expose GW gaskets to temperatures above 400°C.

Store in a dry environment.

Do not bend the GW gaskets.

Avoid any mechanical processing of the gaskets.

Ensure the surface is clean when in use.